Abraham Lincoln

If given the truth, the people can be depended upon to meet any national crisis...

Abraham Lincoln

If given the truth, the people can be depended upon to meet any national crisis...

Guildford news...

for Guildford people, brought to you by Guildford reporters - Guildford's own news service

Guildford news...

for Guildford people, brought to you by Guildford reporters - Guildford's own news service

A Glimpse Of Women Munitions Workers During The First World War

Published on: 2 Jul, 2022

Updated on: 5 Jul, 2022

By David Rose

With a number of light engineering factories in Guildford during the First World War, it’s not surprising that women were employed too, as the firms produced munitions for the war effort.

Pictured are some of the women who were employed by the machine-tool firm Drummond Bros at its factory at Rydes Hill, Guildford during the First World War. Second from left in the middle row is Edith Harriett Collyer. It’s a long shot, but can any of the other women be named? If you can help leave a comment in the box at the foot of this story. Click on the images to enlarge in a new window.

At its factory at Broadstreet, Rydes Hill, lathes and other machine tools were made by Drummond Bros.

From the outset of the First World War, Drummonds supplied the Admiralty, War Office, Mechanical Transport and Royal Flying Corps with machine tools.

From July 26, 1915, it came under direct Government control. This meant it had to take orders direct from the Ministry of Munitions including the prices it set. Its work was then solely on making lathes and associated materials as fast as possible for other factories throughout Britain.

An old pedal-driven Drummond lathe found by Dragon editor Martin Giles near St Andrews, Scotland in 2013 with the manufacturer’s nameplate enlarged.

Drummonds developed new machinery as the demand for new types of machines to make munitions increased. Work at Rydes Hill went on around the clock with a peak workforce of 460 men, supplemented by thirty-five women who were employed for clerical duties.

The above photo shows some of the women who worked at Drummonds during the First World War. It has been supply by Graham Collyer, my former editor at the Surrey Advertiser, who is keen on his family’s history.

He writes: “The photo has been sent to me as a result of a family downsize. The tall lady second left in the middle row is Edith Harriett Collyer (1876-1984). She was born in Elstead, the fourth of seven children of James Collyer, my two times great uncle, and his wife Eliza (nee Prentice).

“To me, she was Aunt Edie, married to Tom Jordan with a daughter Monica, and she lived in Hersham, where she died.

“Until I received the picture I had no knowledge of her war work. In her teens she worked in domestic service in London, mainly, and in the 1911 census was a parlourmaid at St Thomas’s Hospital in London.

“Her father was the tenant farmer at Springfield Farm beside Elstead Green, but was forced to leave following an accident and moved to manage an estate called Yeoveny at Staines, which is now under the Wraysbury reservoir close to the A30 junction with the M25.

“He died in 1900 and his widow eventually moved to Guildford to live with her youngest child, Harry, who was an apprentice compositor with the printers Billings and had a company house at 1 Caxton Gardens, Weston Road.

“Edie was living at 1 Caxton Gardens when she married at Stoughton parish church in July 1919 (as was her husband Tom), but had no occupation listed. Tom was an aircraft fitter.

“They remained at Caxton Gardens until at least 1926 and then the next address I have for them is 56 Beckingham Road, Guildford.

“The house was named Brampton, which was the place in Cumberland where Tom was born.

“Why there is a mystery, since his father was very much a Surrey man from around Westcott and Friday Street, and then Byfleet.

“The Brampton move lasted only a few years before the family returned to Surrey.

“Tom and Edie’s daughter Monica did not marry and lived at home with her parents. She is listed as a shorthand typist in the 1939 Register and I have a feeling she worked at the Ministry Agriculture, Fisheries & Food (MAFF) offices on Epsom Road for a number of years.”

Fire at Drummonds halts production

In my book, Great War Britain Guildford Remembering 1914-18, David Rose in association with the Guildford Institute (published by The History Press in 2014), I wrote about Guildford factories that produced munitions including Drummonds and a fire there that halted production. Here’s what happened….

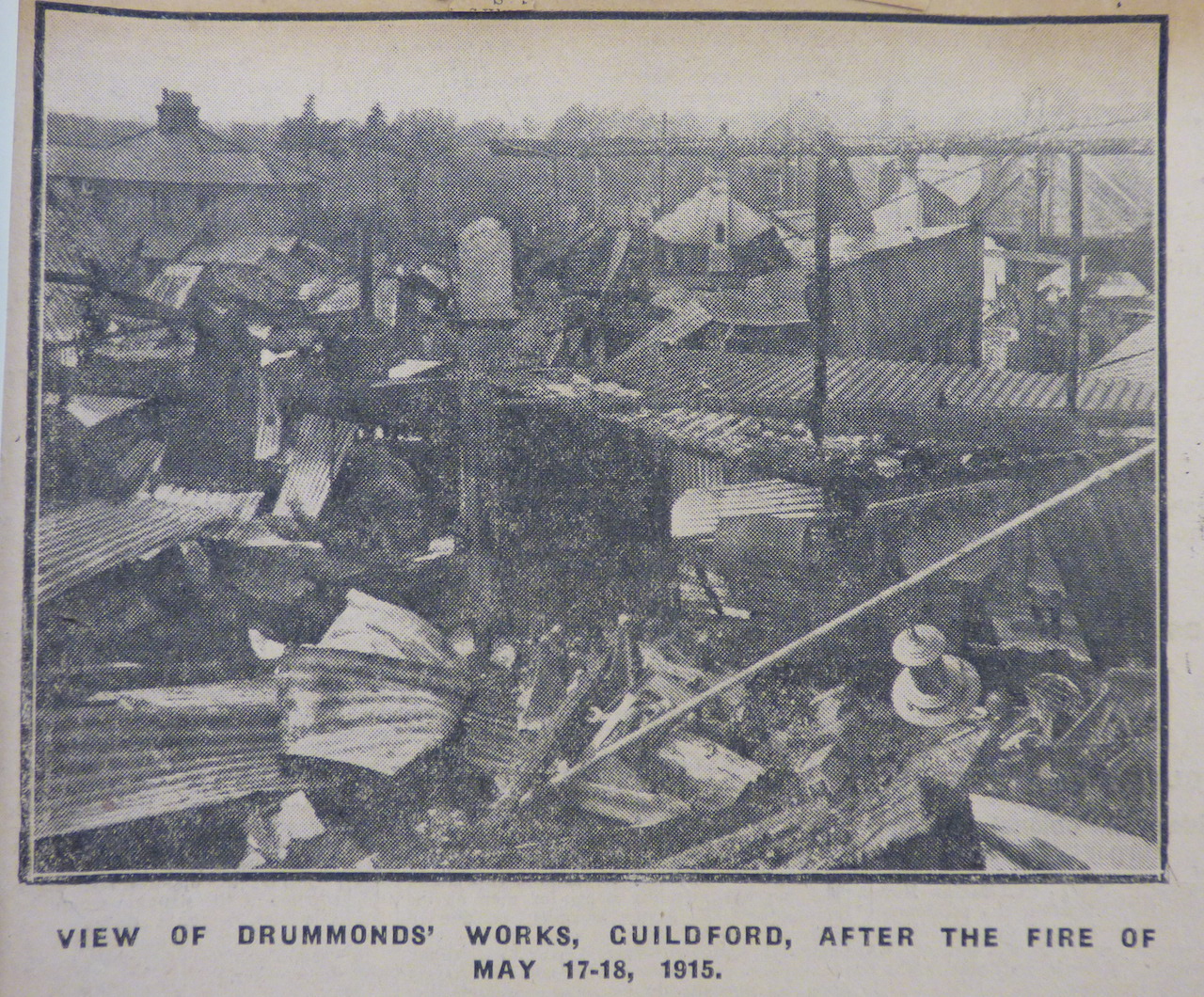

Newspaper cutting showing the aftermath of the fire at Drummonds during the First World War. Courtesy of the Guildford Institute collection.

Production was halted when a blaze destroyed part of the factory in the early hours of May 18, 1915. The Surrey Times reported that the factory’s night watchman, John Harding, on his round at 1pm noticed that a fire had broken out in the factory’s engine room.

The report stated: “The works were constructed of wood and corrugated iron, and covered an area of about one and a half acres, and it can be easily imagined how rapidly such buildings would be prey to a fire once it got hold.

“The fire brigade received the call just after one o’clock and turned out with the motor engine in four minutes. On arrival they found the whole place a mass of flames, and the roof falling in.”

The report added that there was a tremendous explosion that could be heard as far away as Camberley and that people came hurrying to the scene thinking that a Zeppelin had dropped a bomb.

The explosive was, however, due to a cylinder containing compressed air being blown apart.

An extension to the factory and three cottages for workers had just been built, while the fire was in the original part. So the firemen concentrated their efforts on preventing the blaze reaching the new buildings, which they did successfully, the fire being put out by 3.30am.

Interviewed by the Surrey Times soon after the fire, Arthur Drummond said: “At the present time we have between 280 and 300 hands engaged on the works, and the whole of them will be paid their full wages on condition that they do not leave the town, and hold themselves ready to return to work immediately they are called upon.

“We shall arrange for the new power to be installed at the earliest possible moment and the new machinery is already on order.

“I was ordered by telephone this morning, and I am going to London today to expedite matters.

“As you know, there is considerable difficulty at the present time in not only getting machinery, but in the delivery of it, but being a Government department, we can rely on Government help in expediting the delivery.

“Fortunately the machinery that has been destroyed is largely of a class that can be replaced, whereas the machinery that has been saved would have been very difficult to replace.

“We shall probably put the men on day and night work so as to make up the set back caused by the fire and by that means we hope to be able to fulfil our Government contracts completely. It is possible that we shall not drop a single item of our Government work.”

He added that he did not think the fire was caused by foul play.

Drummonds’ later history and what’s there now

I featured Drummonds in my book Guildford Remember When, co-written with Bernard Parke and published by Breedon Books in 2007.

During the Second World War Drummond Bros undertook military contracts that included cranks and propeller shafts for the Bristol aircraft engine being cut on Drummonds’ own Maxicut No.2 lathe.

Founder Arthur Drummond retired from the board of directors in 1946. His successor was George Hickman, who had started as an apprentice with the firm in its early days. Hickman went on to serve the company for 60 years.

The company’s share capital was taken over by the Asquith Machine Company in 1953. Thirteen years later it became the Drummond division of Staveley Machine Tools Ltd.

Halcyon days in the postwar era brought further expansion. The workforce was increased to more than 300 in the 1960s and it ran a first-class apprenticeship scheme.

Employees were well looked after, many of them working there for several decades. It was not unusual for half of the Portsmouth train to be booked for the works’ summer outing.

The 1970s saw lathes made at Rydes Hill being shipped to the ZIL Car plant in Moscow, as part of a £14 million installation of an automated production line.

The company’s fortunes began to slide in 1977 with a disastrous project known as the Multi-turn 200 lathe. It was an automatic machine with an early type of computer control. The firm went ahead and made 20 of them without a prior order. It was a huge investment and less than a third were sold the rest being scrapped.

The firm did not recover and in 1980 the majority of the workforce was made redundant. Within two years only four employees remained, servicing machines that were still under guarantee. Within a year they had gone and the factory was then demolished and has been replaced by a business park currently named The Pines Trade Centre.

Responses to A Glimpse Of Women Munitions Workers During The First World War

Leave a Comment Cancel replyPlease see our comments policy. All comments are moderated and may take time to appear.

See Dragon story: GBC’s Explanation of Major Land Sale Notice Error ‘Borders on Arrogant’ Says Councillor

Recent Articles

- Drug Gang Jailed: Their Activities Were Directed From Behind Bars, Court Told

- Planning Inspector Allows Another High-rise for Woking

- Letter: Why These False Flag Political Stunts?

- Highly Regarded Joint Strategic Director Quits Guildford & Waverley Councils

- Birdwatcher’s Diary No.302

- Diocese of Guildford Appoints New Registrar and Legal Advisor

- ‘One in Five’ Surrey Police Officers Seeking Another Job

- Insights: Lead from the Front on Values

- New Investment Will Help Surrey Fire and Rescue Service Improve Training Facilities

- Letter: Are the PCC Candidates Relying on Their Party Labels?

Recent Comments

- Jan Messinger on Birdwatcher’s Diary No.302

- Ben Paton on ‘What Is Ofwat Doing?’ Asks a Customer

- Ben Paton on Insights: Lead from the Front on Values

- Jim Allen on Insights: Lead from the Front on Values

- David Smith on ‘It Will Grow’ Says Councillor About Replacement Tree in Upper High Street

- Penny Panman on ‘It Will Grow’ Says Councillor About Replacement Tree in Upper High Street

Search in Site

Media Gallery

Dragon Interview: Local Artist Leaves Her Mark At One of England’s Most Historic Buildings

January 21, 2023 / No Comment / Read MoreDragon Interview: Lib Dem Planning Chair: ‘Current Policy Doesn’t Work for Local People’

January 19, 2023 / No Comment / Read MoreA3 Tunnel in Guildford ‘Necessary’ for New Homes, Says Guildford’s MP

January 10, 2023 / No Comment / Read More‘Madness’ for London Road Scheme to Go Ahead Against ‘Huge Opposition’, Says SCC Leader

January 6, 2023 / No Comment / Read MoreCouncillor’s Son Starts Campaign for More Consultation on North Street Plan

December 30, 2022 / No Comment / Read MoreCounty Council Climbs Down Over London Road Works – Further ‘Engagement’ Period Announced

December 14, 2022 / No Comment / Read MoreDragon Interview: GBC Reaction to the Government’s Expected Decision to Relax Housing Targets

December 7, 2022 / No Comment / Read MoreHow Can Our Town Centre Businesses Recover? Watch the Shop Front Debate

May 18, 2020 / No Comment / Read More

Maureen Shettle

July 3, 2022 at 11:06 am

You might be interested to know that George Hickman was Chief Officer of Guildford Fire Brigade between 1915 and 1935. He was appointed to the post just a few weeks after the fire at Drummonds.

David Rose replies: Many thanks for that Maureen.