Abraham Lincoln

If given the truth, the people can be depended upon to meet any national crisis...

Abraham Lincoln

If given the truth, the people can be depended upon to meet any national crisis...

Guildford news...

for Guildford people, brought to you by Guildford reporters - Guildford's own news service

Guildford news...

for Guildford people, brought to you by Guildford reporters - Guildford's own news service

Neighbours Amazed by Speed of Construction – From Base to Roof in Five Days

Published on: 28 Apr, 2013

Updated on: 2 May, 2013

How long would you expect it to take to build a house? A quick check on the internet shows that 15 weeks might be a reasonable expectation. But in Artillery Road, off Woodbridge Road, a building has been erected in just five days and should be complete in two weeks!

This time last week it was just a flat concrete base. Now the entire shell with roof frame is in place! Neighbours have been amazed with the speed on construction.

Robin Lewis, sales director at TREECO (Timber Renewable Engineered Eco Construction), the company responsible, said: “The project on Artillery Road in Guildford is going to be wind and water tight in a week and should be ready to receive the second fix electrics, plumbing, kitchens and bathrooms after two weeks.

“It is an incredibly tight site with no space for material storage so our prefabricated system was ideal. The client is replacing four garages with four one-bedroom flats. We have managed to keep the road open at all times and have been able to unload the sections of the building directly from the lorry on to the foundations. The whole building including the windows came on two HGV lorries.

“Currently we are using a Polish company’s own workmen to construct the houses, but our long-term aim is to train up British workers. We are considering employing ex-servicemen personnel as the system is best installed by teams used to working together and we are already receiving projects nationwide, which would probably suit troops used to being posted overseas for months at a time.

TREECO is the exclusive UK distributor for a Polish closed panel timber frame company that has been building this way for 20 years in Poland, Germany, Sweden, Norway and the Czech Republic. It carries out as much of the prefabrication in the factory as possible.

Mr Lewis continued: “The prefabrication reduces the time of a build, the disturbance to neighbours and waste produced on site and greatly increases the quality of the final product as it can be fabricated in a factory environment, protected from the elements and uses laser guided machines to guarantee production accuracy. The buildings are incredibly airtight with great attention paid to the detailing around windows and produce incredibly good ‘U Values’ [i.e. low rates of heat loss].

“Unlike many of the German companies that have featured on [the TV programme] Grand Designs, with a limited number of styles, we can provide a totally bespoke service and using modern cladding technologies can provide whatever design and finish the client requires.”

The timber used, which is the main element of the product, comes from Poland but the entire product contains components from across Europe. There are British, German, Austrian and French components. The mechanisms and frames for the windows are normally German as they are market leaders in this technology.

TREECO work with a local construction management company, Woodley Lucas based in Seale, to provide clients with a turnkey solution. Once a client has planning permission the two companies work hand in hand: TREECO building the house, in factory, while Woodley Lucas organises foundations, installation of any access roads, services and

Robin Lewis concluded: “We have been hugely grateful for the help and kind words of many of the neighbours of the Artillery Road project, there has been a huge amount of interest from both locals and passing architects and developers and as a company we wanted to thank everyone for their encouragement and support, even the traffic wardens have been really helpful. The installation team from Poland have really enjoyed working in England and are already big fans of English sausage sandwiches.”

Caroline Reeves a borough councillor (Lib Dem, Friary & St Nicolas), who lives in Artillery Road, said: “Those of us living nearby have been simply amazed by the speed of construction. In just a few days we have a building in place that replaces some garages which, frankly, were a bit of an eyesore. It makes me wonder whether there are some significant savings to be gained for other housing projects in both the private and public sector.

“It is good to hear of plans to transfer skills to British workers and that, in the mean time, our Polish friends have been enjoying our local ‘cuisine’. I hope they realise there is more to it than sausage sandwiches!”

Responses to Neighbours Amazed by Speed of Construction – From Base to Roof in Five Days

Leave a Comment Cancel replyPlease see our comments policy. All comments are moderated and may take time to appear.

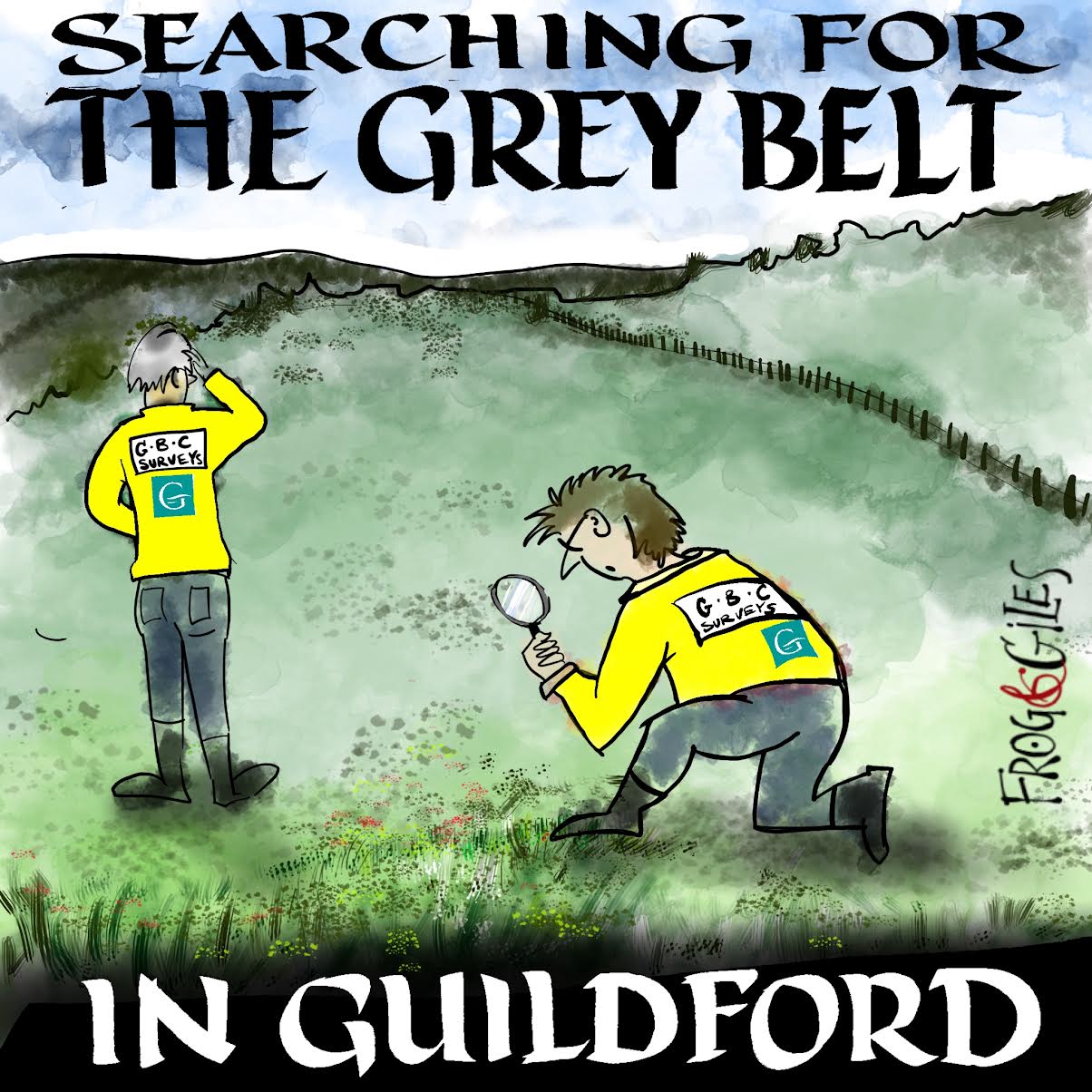

"Found any?" - "Nope, it all looks green to me!" (See Opinion: The Future is Congested, the Future is Grey)

www.abbotshospital.org/news/">

Recent Articles

- Latest Evidence in Sara Sharif Trial

- Ash’s New Road Bridge Is Named – and November 23rd Is Opening Day

- Class A in Underwear Leads to Jail Sentence

- Historical Almshouse Charity Celebrates Guildford in Bloom Victory

- Notice: Shalford Renewable Showcase – November 16

- Firework Fiesta: Guildford Lions Club Announces Extra Attractions

- Come and Meet the Flower Fairies at Watts Gallery

- Updated: Royal Mail Public Counter in Woodbridge Meadows to Close, Says Staff Member

- Letter: New Developments Should Benefit Local People

- Open Letter to Jeremy Hunt, MP: Ash’s Healthcare Concerns

Recent Comments

- Paul Spooner on Ash’s New Road Bridge Is Named – and November 23rd Is Opening Day

- Harry Eve on Opinion: The Future is Congested, the Future is Grey

- Nigel Keane on Letter: New Developments Should Benefit Local People

- Nathan Cassidy on Updated: Royal Mail Public Counter in Woodbridge Meadows to Close, Says Staff Member

- T Saunders on Opinion: The Future is Congested, the Future is Grey

- Jim Allen on Updated: Royal Mail Public Counter in Woodbridge Meadows to Close, Says Staff Member

Search in Site

Media Gallery

Dragon Interview: Local Artist Leaves Her Mark At One of England’s Most Historic Buildings

January 21, 2023 / No Comment / Read MoreDragon Interview: Lib Dem Planning Chair: ‘Current Policy Doesn’t Work for Local People’

January 19, 2023 / No Comment / Read MoreA3 Tunnel in Guildford ‘Necessary’ for New Homes, Says Guildford’s MP

January 10, 2023 / No Comment / Read More‘Madness’ for London Road Scheme to Go Ahead Against ‘Huge Opposition’, Says SCC Leader

January 6, 2023 / No Comment / Read MoreCouncillor’s Son Starts Campaign for More Consultation on North Street Plan

December 30, 2022 / No Comment / Read MoreCounty Council Climbs Down Over London Road Works – Further ‘Engagement’ Period Announced

December 14, 2022 / No Comment / Read MoreDragon Interview: GBC Reaction to the Government’s Expected Decision to Relax Housing Targets

December 7, 2022 / No Comment / Read MoreHow Can Our Town Centre Businesses Recover? Watch the Shop Front Debate

May 18, 2020 / No Comment / Read More

Peter Bullen

April 29, 2013 at 10:54 am

From the sound of it, such buildings should cost less than traditionally built structures – which could be good news for helping to meet Britain’s severe housing shortage.

I’m sure we are not the only couple who read Guildford Dragon NEWS who live in a similar timber-framed, prefabricated bungalow sold by a local company, Guildway. Ours was erected about 40 years ago and is a well insulated, snug, draught-free home.

John Andrews

April 30, 2013 at 10:40 am

Looks like an excellent system perhaps a solution to some of the countries housing problems. Well done TREECO and Woodley Lucas