Abraham Lincoln

If given the truth, the people can be depended upon to meet any national crisis...

Abraham Lincoln

If given the truth, the people can be depended upon to meet any national crisis...

Guildford news...

for Guildford people, brought to you by Guildford reporters - Guildford's own news service

Guildford news...

for Guildford people, brought to you by Guildford reporters - Guildford's own news service

Sandiacre Horticultural Nursery Extends With Amazing New Site

Published on: 15 Feb, 2019

Updated on: 16 Feb, 2019

By Hugh Coakley

Driving out of Guildford on the Aldershot Road just past Fairlands, you can’t help but notice a huge and impressive new, three-acre glasshouse on the left.

The Guildford Dragon NEWS was intrigued and asked the owner, Royden Kemp, to tell us a bit about it.

Here, Mr Kemp explains how his family’s Sandiacre Nursery in Wood Street Village started and about its new project at Clasford Farm.

Aerial view of the new three-acre (or 12,000 sqm) glasshouse on the Aldershot Road. Click on the images to enlarge in a new window.

The current R. C. Kemp & Sons was started in 1945 by my father, along with my mother.

They left war-torn London inspired by growing six tomato plants on a balcony in St Paul’s Avenue, Cricklewood Broadway.

They had earlier placed an advert in Daltons Weekly asking if anyone had nursery land for sale. Out of four responses they choose four acres of land and a building plot in Frog Grove Lane, Wood Street Village.

It was named Sandiacre Nurseries after my father’s birthplace in Sandiacre in Derbyshire.

He visited the bank manager soon after and asked for a loan to build his first glasshouse, but after consideration, his request was rejected. The reason the bank manager gave for refusal was that his bank considered my father’s chosen profession to be a “precarious occupation”.

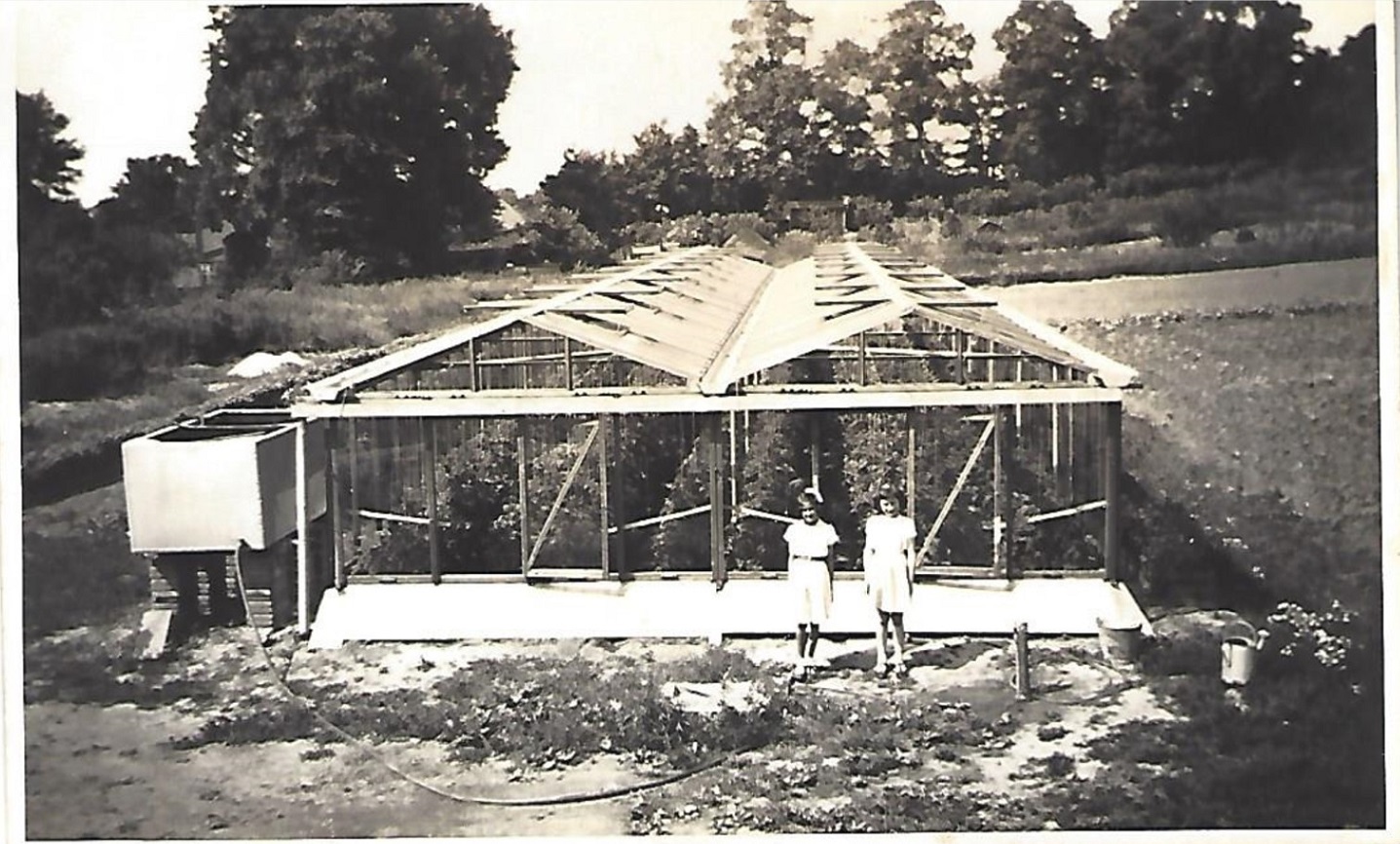

Sandiacre Nurseries at 148 Frog Grove Lane in 1959. The water tanks look tiny compared to what is now required.

Some 74 years on, I would still agree with that statement, but with the application of hard work, sometimes bordering on the fanatical, the Kemp family has survived and prospered as a local business come good over all those years.

I went into a partnership with my father in 1976 at the age 19 and have steered the business over the last 43 years to even greater heights along with my wife Melanie.

We have had four children. The two boys, Andrew and Peter, are now firmly part of the business and are the next generation – gradually learning their craft to continue into the future.

Our two girls, Holly and Emily, are both very competent equine managers and are fully involved in shaping the progress of the equine stabling business on site.

The company acquired Clasford Farm some 20 years ago. When it came to expanding the nursery business, we applied for planning permission to build three acres of new glass on the front field adjacent to the road.

Planning permission was duly granted by Guildford Borough Council, balancing the environmental constraints of the local area against the need to support local business expansion. The new project was started in June 2018 with a view to finishing ready for the bedding plant season of 2019.

The heated zone of the glasshouse is finished and geranium production started on February 4. The new nursery is only six minute’s walk across the fields from Sandiacre Nurseries so it allows the two sites to share staff quickly during peak workloads.

The home nursery in the early days used to produce crops of tomatoes and lettuces along with cut flower crops of chrysanthemums.

The winter of 1962-63 saw a disaster when a block of glass with a lettuce crop in was flattened by the sheer weight of snow.

But my parents soldiered on.

My only biblical disaster was the storm of January 19, 1990 (not the so-called great storm of 1987… but one with far more ferocious winds than that) when in the early afternoon, around 2pm, winds reached well over 100mph and in 20 seconds, a glasshouse, holding young primroses, was stripped of 200 sheets of glass. We had no insurance cover and it needed a complete rebuild.

As the mid-1960s arrived, the garden centre concept began to develop in the local area and Woolworths and others needed young flowering plants to be grown in packs and pots.

Sandiacre Nurseries turned into a wholesale bedding plant nursery and remains that today. The new site is an expansion of that need.

The new site provides for three acres of new glass all under one roof as the site is flat, unlike the home nursery that is built on a hillside. This gives us a far more efficient site.

In addition, the whole three acres will be watered automatically with 16 watering booms covering the whole of the house. We have also just installed our first compost mixing/tray filling and automatic transplanting line.

Although these new innovations do save time and labour there is still a huge requirement for production staff whose jobs include laying the production on the floor of the glasshouse and then picking it all up again as it gets sold to local garden centres.

We are currently recruiting and hope to fill our vacancies first from local people. The site will require some eight to 12 additional staff.

As part of the planning permission, we had to make provision for any future storm when the glasshouse roof could potentially produce 75,000 gallons of rainwater for every inch of rain that falls.

This has been covered by the provision of 16 above ground water tanks capable of holding a third of a million gallons of rainwater, which is then allowed to drain into the public waste water system over the next 72 hours.

During that time though we can harvest up to 100,000 gallons of rainwater and store them in the additional four water tanks at the front of the nursery where we can use it to water the plants. Rainwater is far better as it does not contain the calcium that mains water does.

In addition to the water harvesting, we have installed 185 photovoltaic panels on the roof of the building. At their peak in July these are capable of producing 50Kw of power, most of which will be exported back into the grid, enough to power a considerable number of local homes. Even in the winter, adequate power is produced to make the nursery completely self-sufficient in the day for its electricity supplies. For the future, battery storage will keep us off-grid through the night as well.

An environmental computer is also installed. This allows set points to be set up for venting and heating temperatures. It will automatically open vents when required and close thermal screens at night to hold in the day’s heat. The computer will monitor increasing wind speed and direction and open vents first on the leeward side of the glasshouse and of course, shut them when winds reach a certain threshold.

As the business moves into the next generation, I see my job as showing them what it takes to be successful. There is little that cannot be achieved by a little sweat and hard work and the wholesale bedding industry is just one of those businesses that will always require that.

Responses to Sandiacre Horticultural Nursery Extends With Amazing New Site

Leave a Comment Cancel replyPlease see our comments policy. All comments are moderated and may take time to appear.

See Dragon story: GBC’s Explanation of Major Land Sale Notice Error ‘Borders on Arrogant’ Says Councillor

Recent Articles

- What More Does the Solace Report Tell Us About the Housing Revenue Account Investigation?

- Guildford Has a New Mayor

- Notice: Exhibition – Ripley – World Famous Cycling Mecca

- Volunteer Organisers for the Poppy Appeal Urgently Needed

- ‘Damning’ Report Debated at Council Meeting – CEO Calls for Councillors to Come Together

- Surrey Children’s Services Improvement Recognised by Ofsted

- Independent Guildford Stationers Are ‘Top of the Shops’

- Birdwatcher’s Diary No.304

- Cyclist Dies in Peaslake

- Surviving Strategic Director Quits to Take Up CEO Role with a West Sussex Council

Recent Comments

- H Trevor Jones on ‘Damning’ Report Debated at Council Meeting – CEO Calls for Councillors to Come Together

- Paul Spooner on ‘Damning’ Report Debated at Council Meeting – CEO Calls for Councillors to Come Together

- Michael Duff on Birdwatcher’s Diary No.304

- Jane Thomas on Opinion: The Majority of People in GBC Have Had Enough of Failure

- Jo Davids on Independent Guildford Stationers Are ‘Top of the Shops’

- Anthony Mallard on Independent Guildford Stationers Are ‘Top of the Shops’

Search in Site

Media Gallery

Dragon Interview: Local Artist Leaves Her Mark At One of England’s Most Historic Buildings

January 21, 2023 / No Comment / Read MoreDragon Interview: Lib Dem Planning Chair: ‘Current Policy Doesn’t Work for Local People’

January 19, 2023 / No Comment / Read MoreA3 Tunnel in Guildford ‘Necessary’ for New Homes, Says Guildford’s MP

January 10, 2023 / No Comment / Read More‘Madness’ for London Road Scheme to Go Ahead Against ‘Huge Opposition’, Says SCC Leader

January 6, 2023 / No Comment / Read MoreCouncillor’s Son Starts Campaign for More Consultation on North Street Plan

December 30, 2022 / No Comment / Read MoreCounty Council Climbs Down Over London Road Works – Further ‘Engagement’ Period Announced

December 14, 2022 / No Comment / Read MoreDragon Interview: GBC Reaction to the Government’s Expected Decision to Relax Housing Targets

December 7, 2022 / No Comment / Read MoreHow Can Our Town Centre Businesses Recover? Watch the Shop Front Debate

May 18, 2020 / No Comment / Read More

Brian Evans

May 12, 2022 at 3:20 pm

I was prompted to visit your site following a purchase of plants today. Sandiacres name appeared on the instruction label and a very interesting commentary on the development of the company.

It is good to have a local supplier and my what a wonderful greenhouse!

This is my third purchase of plants this year – all from Sandiacres – and yes they are A1 quality.